New York Entrepreneur Makes Largest One-Time Purchase

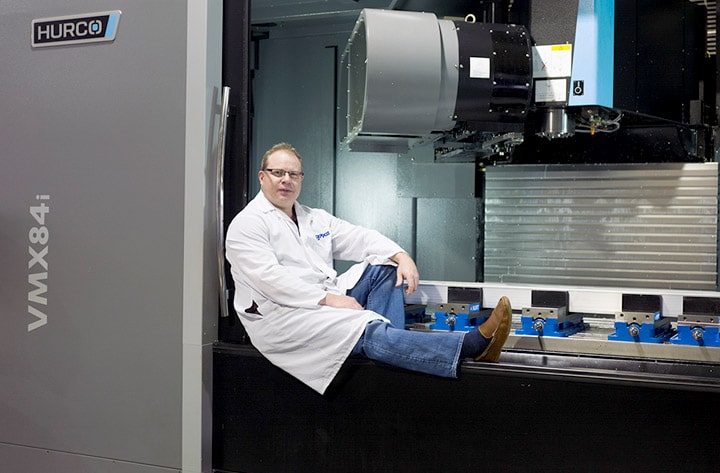

INDIANAPOLIS—Charles Boyce, owner of Boyce Technologies in New York, broke the Hurco USA record for the largest single purchase of Hurco CNC machines in the division’s history. Boyce Technologies designs…

Read More