JTEKT Machinery Americas

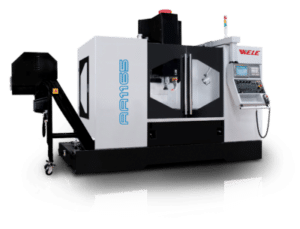

Being at the forefront of the industry means having the right machine tools for the job. JTEKT Machinery’s complete line of machines range from vertical and horizontal machining centers to grinding machines, bridge and gantry machines to turning centers. Developed with the operator in mind, JTEKT machines utilize Fanuc and JTEKT controls for ease of use and optimal efficiency. With first-class design, unsurpassed technology, and the support of thoughtful engineering, JTEKT Machinery builds more than just a great machine; it manufactures precision and performance at its finest.

Read the news release about Brooks partnership with JTEKT

value.

The JTEKT Machinery Advantage

Experience 20% plus more profitability and the lowest total cost of ownership. JTEKT Machinery maintains a competitive advantage with the lowest total cost of ownership and superior product support. JTEKT Machinery’s quality of components and energy efficient designs allow for JTEKT machine tools to typically draw less electricity than other in-class machines, while still-outperforming them in cutting capability.

Most Reliable Machine Tool

Average JTEKT Machinery Horizontal Machining Center owner spends less than 1% of the machine’s initial investment cost on parts and service per year across the life of the machine tool.

FOR A $300,000 MACHINE, EXPECT LESS THAN $3,000 PER YEAR FOR MAINTENANCE EXPENSE AFTER WARRANTY PERIOD EXPIRES.

Most Reliable Spindles

Known throughout the metal cutting industry as the most rigid and dependable machines, JTEKT Machinery’s spindle is manufactured under strict quality control. The spindle is installed in the machine only after ensuring all allowable limits have been maintained.

From the first FH-J series horizontal machining center sold in 2008, the very first spindle repair case was done in 2015 and only 2% of the FH-J series sold have spindles replaced.