The Yama Seiki Swiss turning centers are the best solution available for working with pieces smaller than 32mm. They offer an incredibly rigid body, faster through put, and an extremely large variety of tooling choices. In addition these machines are available with sub-spindle, live tooling and bar-feeder options.

The Yama Seiki Swiss turning centers are the best solution available for working with pieces smaller than 32mm. They offer an incredibly rigid body, faster through put, and an extremely large variety of tooling choices. In addition these machines are available with sub-spindle, live tooling and bar-feeder options.

With many of the standard features being similar between the SD Series and the SW Series you may not know the difference between the two. The SD Series is perfect for those customers with minimal floor space. Its compact design really gets the most bang for your buck. The features of this machine create the friendliest working conditions possible. The SD Series is environmentally friendly and easy to maintain with its pneumatic system rather than a more traditional hydraulic system. The slide ways are bonded with Turcite B which eliminates slipping while maintaining accuracy and minimizing wear. The other axes maintain high accuracy positioning regardless of speed through the use of high precision linear guide ways.

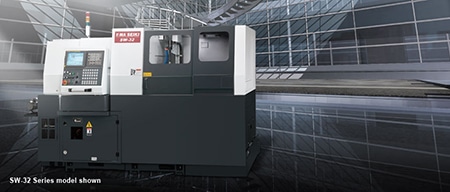

The SW Series is more of a tool system as it offers a variety of operations including turning, milling and cross drilling. All these features are offered through different combination of power systems: main-spindle, sub-spindle, front-end tool, rear-end tool, c-axis, and live tools. The biggest benefit to the SW Series is that two operations can be machined simultaneously and the workpiece can be finished at one time. Another feature of the SW Series is that you can select either a bush type or bushless type spindle depending on your requirements. The bush type rotates at an incredibly high speed which causes less surface damage and increases efficiency for work performance. The bushless design is the perfect choice for machining cold forge bars as it does an excellent job of minimizing material costs.

Regardless of whether you chose the SD or the SW Series both include main spindle motor configuration, a spindle brake, a C-axis feature, and rigid tapping. Both units include a coolant pump, coolant flow switch, coolant level switch and roll-out coolant tank as well as the option for an oil skimmer and a high-pressure coolant system.

Brooks has proudly represented the Yama Seiki Swiss Turning Centers throughout the New England area for years and is looking forward to meeting with you to discuss in greater detail the differences between these two series as well as the specifics of your application. Give us a call today to get an appointment scheduled.