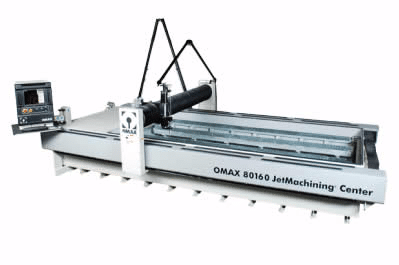

If you’re using a Solids Removal System (SRS) with your abrasive waterjet, you can greatly enhance the system’s effectiveness by running the tank cleaning program in OMAX Make. This program runs a stream of water back and forth across the entire table, agitating abrasive and material waste that tends to collect in piles along the bottom of the tank. The SRS can then efficiently remove the circulating waste particles from the tank.

If you’re using a Solids Removal System (SRS) with your abrasive waterjet, you can greatly enhance the system’s effectiveness by running the tank cleaning program in OMAX Make. This program runs a stream of water back and forth across the entire table, agitating abrasive and material waste that tends to collect in piles along the bottom of the tank. The SRS can then efficiently remove the circulating waste particles from the tank.

There are a few recommended steps to properly maintain your waterjet tank. On a regular basis wash away the abrasive accumulation from the machine and the work area. Remove all garnet, sludge and slugs from the bottom of the tank. Inspect individual slats for wear – replace and/or rotate as needed. Clean the outlet water filter and regularly run the tank cleaning program. On a monthly basis check the anti-bacterial chemicals for the tank water which control the tank odor and bacteria growth. Always check your system manual for full details on proper tank maintenance.