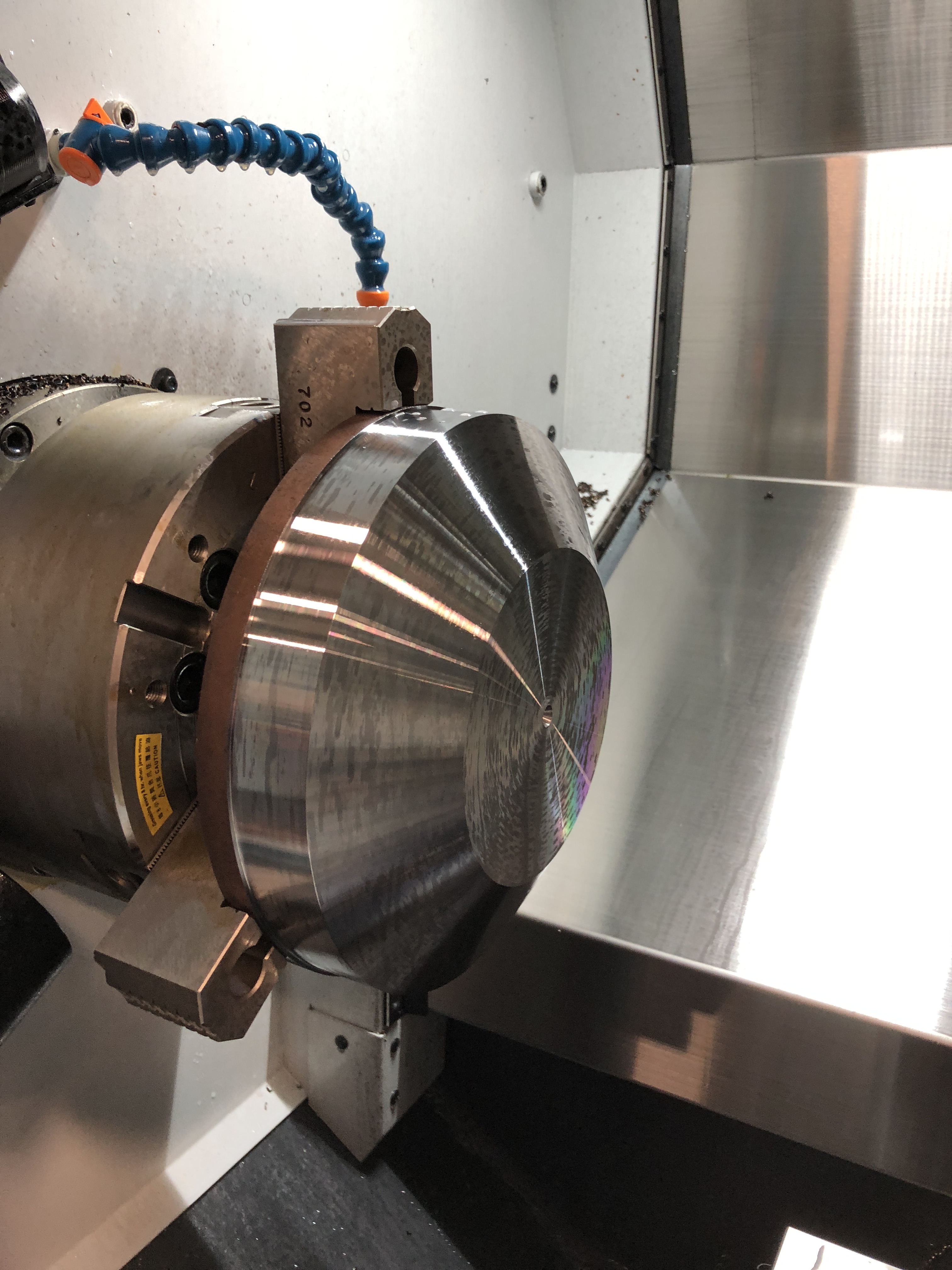

Like all of the GA series horizontal turning centers, the GA2800 is designed to handle heavy-duty turning applications, such as the one pictured here, while maintaining the highest accuracy. This part is 10” in diameter and made of 4150 steel – not a problem for the GA2800. While every shop needs a machine that can deliver on accuracy and reliability, those with a Yama Seiki machine also get the fastest cycle times possible. This system is known world-wide for its incredible ability to hold tolerance at maximum speeds.

Some key features of the GA Series include:

- Extra-large Z-axis servo motors which provide the additional thrust necessary to drill big diameter holes with maximum efficiency.

- Powerful high-torque spindles capable of supplying up to 4x the torque output of standard spindles

- Heavy-duty roller bearings that are used to support the spindles. Axes guide ways are made of super-rigid one-piece box ways. These ensure the long lasting durability of the GA-2800.

There are many customer benefits of the GA-2000 series systems. The GA-2000C is incredibly compact allowing for multiple machines to fit into a tight space and allow for more efficient use of operator time. Many New England shops are tight on space so this can be critical for the ability to increase revenue without relocating.

The GA-2000 machines also include a 30° slant wedge bed, which has been designed to provide smoother chip disposal and increased operator comfort without losing system rigidity. In addition, the GA series systems feature a standard programmable base and quill tailstock. The base and quill can be operated using the quill-jog function to allow the operator to make slow, small movements forward while inserting the center into the center hole. The base and quill can also be operated in auto mode which is completely controlled by M-codes with manually adjustable thrust pressure.

The engineers at Yama Seiki understand that there are countless applications for these systems and thus offer 26 models in the GA series to ensure machine capacity both big and small, as well as live tooling features to provide the maximum in flexibility. There’s truly a machine for every shop’s needs. Contact Brooks Associates today to schedule a demo or learn more about how the addition of Yama Seiki’s powerful horizontal turning center could take your business in a new direction.