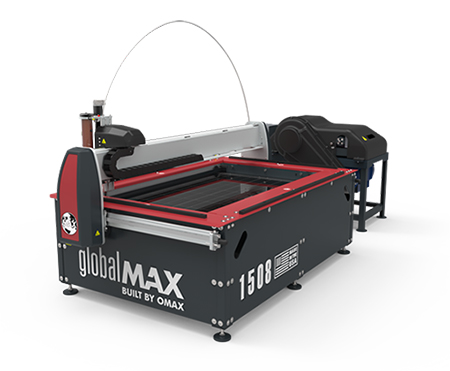

The GlobalMax abrasive waterjet is the latest in a long line of high quality products released by OMAX Corporation. This machine is an affordable, compact unit designed for shops looking to get into their first waterjet, or those with limited floor space. The GlobalMax has been received extremely well since launching a year ago and has now expanded into the international market as well.

The GlobalMax abrasive waterjet is the latest in a long line of high quality products released by OMAX Corporation. This machine is an affordable, compact unit designed for shops looking to get into their first waterjet, or those with limited floor space. The GlobalMax has been received extremely well since launching a year ago and has now expanded into the international market as well.

The cutting area of 2’7” x 5’0” gives customers the maximum opportunity to cut parts while staying within a footprint of only 5’3” x 12’0”. In addition, the OMAX software package ensures maximum material usage through its nesting features and minimal operator training time. This software is so simple to use that most operators are running parts through the machine within just a couple of hours. Unlike other machines that use old or outdated software to keep the price down, the GlobalMax includes the latest 4th generation cutting model to provide the fastest cut speeds possible.

Customers have asked us what the hardware looks like on such an affordable machine, rest assured it’s still the high quality, rigid machine tool that you’ve come to expect from Brooks and OMAX. The new Omega Drive System uses precision tooth engagement to minimize backlash and improve reliability. It provides a far smoother transition from rotary motion to linear motion, when compared to the more traditional rack and pinion drive system. In addition the Omega Drive system requires absolutely no lubrication and eliminates the risk of garnet being drawn to your drive system.

The newly redesigned GlobalMAX pump is the most efficient option on the market converting over 85% of the electrical power into cutting power at the nozzle. Like all OMAX pumps it utilizes direct drive technology which has been proven through thousands of installations to be low maintenance, highly reliable, efficient, and durable. With several pump size options to consider, the Brooks team can help you select the right pump for your application.

Here’s what other owners have said about these incredible abrasive waterjets:

“Because of the OMAX waterjet machine and the ease-of-use with the software, it allows us to nest parts in materials and get more pieces per sheet.”

“In the morning we can go through and cut an entire product out and have a prototype put together because we can do everything in-house and have the accuracy of the waterjet.”