about.

Yama Seiki Horizontal Turning Centers

Get your Yama Seiki horizontal turning centers from Brooks Associates.

GLS-150 Series

High Speed Turning Centers

Packed with industry leading technology and top-quality components, the Yama Seiki GLS series turning centers combine power, strength, and speed to bring you The Ultimate Machining Power®. These high-speed machines will easily accomplish demanding turning applications. With available live tooling, C-axis, and Y-axis capabilities, milling and turning applications may be completed in one single machine.

GLS-1500 Series

High Speed Turning Centers

Based on GLS-150 series, the new GLS-1500 series brings a new 30-degree true slant-bed casting design and optional new single moving live tooling turret. It is designed for demanding turning applications.

GLS-2000L/GLS-3000L Series

Multi-Axis Turning Centers

Yama Seiki offers a broad selection of turn/mill centers with multiple configurations:

- Dual or Single Spindle

- Single or Twin Turret

- Y Axis & Dual Y Axis

- Live Tooling

All of these configurations equal flexibility and minimal part handling. Find the hidden profits in your parts by exploring Yama Seiki multi-task turning centers.

GA Series

Ultra Performance Turning Centers

Engineered to handle heavy-duty turning applications with superb accuracy, the GA series ultra performance turning centers combine extremely powerful high-torque motors, super rigid box way constructions, and large diameter servo indexing turrets to bring you The Ultimate Machining Power®. The GA series will boost your industry competitiveness by increasing cycle times with heavier cuts, faster machine movements, and more efficient cutting of tough materials. You’ll also appreciate the reliability and durability that Yama Seiki machines are known for. Plus, with more standard features than any other machine on the market today, ultra performance turning centers are one of the best investments you can make.

GS-200 Series

Ultra Performance Turning Centers

Packed with industry-leading technology and top-quality components, the Yama Seiki GS-200 series turning centers combine incredible power, strength, and speed to bring you The Ultimate Machining Power®. These powerful ultra performance machines will easily complete demanding turning applications. Two bed lengths with the same advanced design and three spindle sizes offer a total of 6 basic model configurations to suit your manufacturing needs. Furthermore, with available live tooling, C-axis, Y-axis, and sub-spindle capabilities, milling, drilling, and front / back-end turning, applications may be completed in one single machine.

GS-2000 Series

Maximum Performance Turning Centers

Packed with industry-leading technology and top quality components, the Yama Seiki GS-2000 series turning centers combine incredible power, strength, and speed to bring you The Ultimate Machining Power®. These powerful maximum performance machines easily accomplish demanding turning applications. Furthermore, with 2 available live-tooling options, C-axis, Y-axis, and sub-spindle capabilities, milling, drilling, and front / back-end turning applications may be completed in one machine.

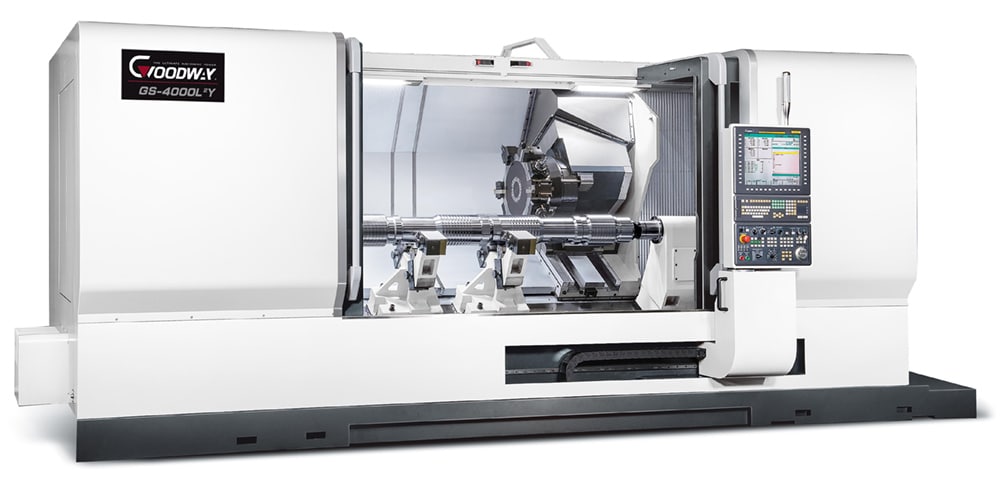

GS-4000 Series

Ultra Performance Turning Series

For those seeking a heavy-duty maximum performance turning center that’s packed with the latest technology, Yama Seiki’s GS-4000 series is the answer. These machines offer incredible turning power, and 37 kW (30min.) 2-speed gear-head spindles, standard on most models, easily turn work pieces up to 24″ diameter. To accommodate various work piece lengths, 4 bed sizes offer maximum turning lengths ranging from 750 ~ 3,000 mm. Live tooling, Y-axis and sub-spindle models further increase machining efficiency and accuracy while reducing man power. Furthermore, Yama Seiki machines are always fully loaded with standard features that are either very costly or unavailable on other machines. Features such as chip conveyor, programmable base tailstock, turning tool holders are standard.

GS-6000 Series

Heavy Duty Turning Centers

Using industry-leading technology and high-quality components, the GS-6000 series ultra high performance turning center combines high power output, high-rigidity construction, large-diameter servo driven turret to quickly and efficiently fulfill your manufacturing needs. It provides a large working range and heavy cutting capability. Additional, live tooling turret and C-axis allow precision turning, milling, drilling and tapping.

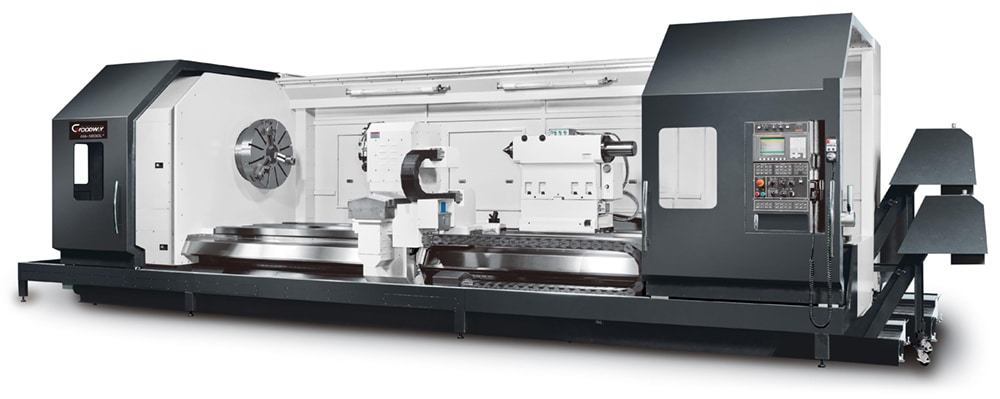

HA Series

Flatbed Turning Centers

The Yama Seiki Flat-bed CNC Turning Center HA series utilizes four high-rigidity box way beds with a three-step gear spindle and servo indexing turret for heavy-duty cutting capability of super large workpiece applications. The HA series is suitable for the oil, energy, aerospace, shipbuilding, and metallurgy industries. The optional four-way toolpost, boring tooling, and high-rigidity steady rest equipment provide a more efficient turning performance for large workpiece applications. The live tooling center and C-axis allow the machine to perform more complicated tasks such as turning, milling, and drilling.

TS-100 Series

Gang Type Turning Centers

Packed with industry-leading technology and top-quality components, the Yama Seiki TS-100 series turning centers combine power, strength, and speed to bring you The Ultimate Machining Power®. These high-speed machines easily complete demanding turning applications. Furthermore, with available live tooling and C-axis capabilities, milling and turning applications can be completed in one machine.

GMS Series

Tool Spindle Type 5-Axis Turning Centers

This hybrid machine combines Yama Seiki’s state-of-the-art machining techniques (X, Y, Z, C axes and live tooling turret) and the features of a machining center, which include the high-speed spindle, ATC system, and B-axis. Complex free-shape machining, tapping, milling, drilling, incline machining, contour machining, and turning are easily completed with the Yama Seiki’s 5-axis turning centers.

GTS Series

Twin Spindles and Turrets CNC Turning Center

Designed for simultaneous turning of work pieces within one machines setup, the GTS series incorporates twin-opposing spindles and turrets with C-axis and live tooling capabilities. This configuration allows both turrets to work simultaneously with one turret at each spindle, achieving ultimate efficiency.

SD/SW Series

Maximum Performance SWISS Turning Centers

Yama Seiki Swiss Type machines are the best solution for work pieces smaller than 32mm. SD & SW series come with a super rigid body, quicker components, and a wide variety of tooling to choose from. They are also available with sub-spindle, live tooling and bar-feeder.

- Fully enclosed splashguards contain chips and coolant for a safe, clean working environment.

- All spindle and servo motors are FANUC alpha i series components to ensure peak machining performance and accuracy.

- C3 class hardened and precision ground ball screws ensure the highest accuracy and durability possible. Plus, pretension on all axes minimizes thermal distortion.

- The auto lubrication system delivers metered amounts of lubrication to the slide ways, ball screws, and vital components. Distribution automatically shuts off during idling to prevent waste.

- Optional A/C controls the electrical cabinet’s temperature and humidity, which extends the life of the electrical components inside.