case studies.

“We went with Hurco because the conversational programming is so easy to use, which means we spend less time training employees.”

-Ed Wrobel, Vice President, Wrobel Engineering

Shop Chooses Hurco for Control Wrobel Engineering (Avon, Mass.) has been providing companies around the globe with engineering, fabrication, assembly, precision sheet metal and precision machining services since 1976. This family-owned business attributes its success to comprehensive customer service built on quality and integrity. Wrobel manufactures components and subassemblies for the military and commercial sectors. They support a diverse group of industries including, medical, electronics, telecommunications, industrial automation, and retail. At their 60,000 square foot facility, 90 employees process one million pounds of 16 and 18 gauge pre-plated steel each year.

Ed Wrobel, Vice President of Wrobel Engineering, says the company wanted to add more CNC mills in order to bring business in-house so they would have more control. Since the average quantity for each job ranges from 1 to 100 or so parts, they needed a CNC mill that would reduce setup time while improving throughput and quality. Ed says another key factor in their decision making process was to find a reliable system that was easy to use so training would be minimal.

Wrobel looked at used equipment, new Haas equipment, and new Hurco CNC mills. Ultimately, he decided to purchase a smaller Hurco VM machining center, X/Y/Z travels of 26 x 14 x 16 inches, then a VMX50, X/Y/Z travels of 50 x 26 x 24 inches, followed by a VMX42 with X/Y/Z travels of 42 x 24 x 24 inches. “We went with Hurco because the conversational programming is so easy to use, which means we spend less time training employees. Additionally, the conversational programming reduces setup time, which is critical to maintaining profit margins when you run a high mix of parts in small to medium volumes to support customers’ JIT initiatives,” says Wrobel.

The machinists at Wrobel find the new probing interface with the part probe and tool setter features of the Hurco control extremely useful in minimizing set up time. Since installing the Hurco CNC machining centers, Wrobel has been pleased with the benefits. The time to train operators has been minimal, he has seen reductions in cycle time, increased accuracy, reduced scrap, and he doesn’t need to outsource machining jobs anymore, which gives him more control over delivery times and quality.

“With the VMX line, Hurco offers a solidly built machine with many upgrades over the competition that work together as a complete system. Those upgrades in the software and in the control have helped us in reaching our goals. With the control’s ease of use and the software built in, work sets up faster. With Brooks we also have a great support network, all the way from their technicians to their willingness to provide that extra bit of training and support that we might need. For us the Hurco network offers a complete solution.”

In addition to quality equipment and skilled craftsmen, Wrobel invests heavily in quality control systems and accreditation. Their list of quality initiatives and accreditations includes ISO 9001- 2008, ITAR Registered, UL Accredited, Six Sigma Methodologies, PPAP (Pre Production Part Approval Process), TUV Certified, Statistical Process Control (SPC), JIT Programs, and Kanban.

As a company, Wrobel’s philosophy revolves around dignity and respect. “We take great care to treat our customers, business partners, vendors, and co-workers with mutual dignity and respect. We have extremely low employee turnover, which provides our customers with the comfort and confidence of having long- term relationships with a team that knows them personally and understands their needs and goals. One of our greatest rewards is hearing a customer describe themselves as part of the Wrobel family.”

In turn, that company philosophy extends to quality products and a customer-centric organization, which enables us to continue investing in leading-edge technologies, such as Hurco CNC mills, to get the job done right the first time.

Process Change Reduced the Need to Outsource

With the help of Brooks Machinery, Automation Development utilizes the Hurco VM1 and VM30 for part manufacturing.

“We truly believe the key to providing quality products is to invest in technology and our employees.”

How does a company sustain an average growth rate of 25 percent during the economic ups and downs of the last 22 years? For Gregor Technologies, a Torrington, Connecticut contract manufacturer that offers a full machine shop, sheet metal fabrication, contract assembly, and design and engineering services, the formula for growth is straightforward: the right machines + the right employees + continual customer responsiveness = sustained growth.

John and Janice Gregorich started Gregor Technologies (www.gregortech.com) in 1989 when John bought his first Hurco—a KMP3 knee mill. Twenty-two years later, Gregor Technologies employs nearly 60 people, has 31 Hurco machine tools, and occupies a 70,000 square foot building. Their success is based on being responsive to their customers while investing in technology that maximizes the shop’s productivity so each job is profitable. When it comes to machine tool technology, Gregor Technologies relies on Hurco.

“I bought my first Hurco because I wanted to have a lean, fast turnaround, customer-focused business,” says John Gregorich. Gregor Technologies is the perfect example of a shop that embraces technology and uses it to be more productive. In turn, they become more profitable. But the Gregor Technologies owners have a healthy skepticism of new technology. “We want to know the benefits and understand the learning curve,” says John Gregorich. This pragmatic approach led Gregor Technologies to Hurco in the very beginning.

While attending a regional manufacturing show, John took a print of a straightforward part to each CNC mill vendor and asked each one to program the part and dry cycle it. Most vendors took 15-20 minutes to program the part and nearly all of them used a CAD/CAM system, which equaled more overhead in John’s mind. Once John arrived at the Brooks Machinery booth, he watched the Hurco distributor program the part in just 5 minutes on the Hurco mill.

As Gregor Technologies has grown, the company’s investment in Hurco machine tools has grown. John bought that first Hurco KM3P knee mill in 1989, followed by a BMC30M, and now the Hurco lineup at Gregor Technologies includes a wide range of CNC machining centers and turning centers, including eight VM1 vertical machining centers, several machines from the performance VMX Series, several TM turning centers, and the newest additions, six 5-axis VM10U machining centers and two 5-axis VTXU machining centers.

This investment in the Hurco VM10U 5-axis machining centers is another example of John and Janice Gregorich’s commitment to invest in relevant technology to meet their customers’ needs more efficiently. Because Gregor Technologies is dedicated to the belief that they are actually an extension of their customers’ companies, they continually work to meet aggressive delivery schedules, cost containment and quality “Dock to Stock” programs of their customers who must succeed in the competitive world of scientific instruments, aerospace, fluid control systems, and homeland security. To exceed their customers’ expectations, Gregor Technologies has used Hurco technology and specialized production software as the building blocks to continually improve and identify efficiencies.

Some shops look at a 5-axis/5-sided machine as too complicated or think the technology is too expensive for the jobs they’re doing. John again approached this investment pragmatically. Because the Hurco control powered with WinMax software is truly easy to learn and easy to use, it only took John two hours to program his part on the VM10U and start making chips. “The five-sided software is great. It’s very simple to use. Once I used the Transform Part Zero feature, everything else fell into place quickly,” says John. “On our 3-axis machines, we had 6 setups. Now I do the same part on our new VM10U and we only have two setups,” says Gregorich.

At Hurco, these collaborative relationships with customers like John and Janice Gregorich foster innovation and drive the Hurco team to develop more technology that helps customers be more productive, more profitable, and grow their businesses. In turn, Hurco grows with their customers. Gregor Technologies shares the same philosophy and is dedicated to investing in the best technology to continually help their customers succeed. In turn, Gregor Technologies continues to succeed.

Says John Gregorich, “We would not be the company we are today if it wasn’t for Hurco.”

“With conversational programming, we don’t have the expense or the bottleneck of a CAD/CAM department.”

-Charlie Gagnon, EMM Precision

Job shop renews efficiency with Hurco When Charlie Gagnon was hired nearly a decade ago by the owner of EMM Precision to get the shop back on track, Charlie’s first order of business was to convert the exclusively G-code shop to a more efficient method. Company founder Robert McIntire told Charlie he wanted the programming in the hands of the non G-code machinists on the floor, not a programmer off in a separate room. After weeks of research, the Hurco machines kept rising to the top of the list. Once EMM Precision purchased their first Hurco, they tossed the G-code manuals and never looked back. Their competitive advantage is competence and determination. “We get it done no matter what it takes. Our customers know they can count on us and that keeps them coming back,” says Charlie.

With three Hurco VM1 machining centers, a Hurco VMX60 machining center, two TMM8 multi-tasking lathes with live tooling, two older Hurco VMCs and a new Hurco VM1P, EMM Precision cranks out thousands of parts per month. Charlie says the Hurco machines do everything from prototype parts to dedicated, 24/7 production work. “We are a true job shop. No customer represents more than 30% of our total revenue. We do a lot of military parts, but we also do parts for aerospace, medical, solar, robotics and automotive,” says Charlie. In addition to EMM Precision’s “get it done” attitude, their pragmatic approach to determining the economics of each job has contributed to sustained efficiency. Because EMM Precision has both a Hurco VMX60 machining center they use as part of a manufacturing cell with their turning centers and two TMM8 slant-bed lathe turning centers with live tooling, they have more options to realize the greatest efficiency for each job. Instinctively, the EMM Precision team knows whether the Hurco TMM8 multi-tasking machine is the best fit or whether they can get the job done faster with the VMX60 and turning center cell.

All of the CNC machinists at EMM Precision use Hurco conversational programming instead of G-code. With conversational programming, EMM Precision doesn’t have the expense or the bottleneck of a CAD/CAM department. The integrated Hurco control and intuitive control software eliminate redundant steps and the tedious task of entering codes. Another advantage of Hurco’s shop floor programming for EMM Precision is the ability to easily train employees. The graphics and straightforward software screens make programming intuitive. In fact, Charlie says the two former G-code employees who run the Hurco machines each day say they can’t believe it’s so easy and always have the feeling there should be “more to do than this.” Both of them say they would never go back to G-code again now that they use the Hurco control. As Charlie likes to say, “When it comes to EMM, blue + white = green!”

More than 50 years after Mr. McIntire started EMM Precision in the rural town of Center Conway, New Hampshire, the new ownership group and its employees continue to foster their founder’s commitment to improve and fine-tune production methods for higher efficiency. Hurco and Hurco’s distributor partner Brook’s Associates are proud to be part of EMM Precision’s success in realizing process improvements that lead to greater productivity.

In the fall of 2008 Wally and David Parmelee (Wepco owners) found themselves at a cross roads in terms of milling capacity for their tool room. Should they continue on with current milling technology (a known entity with zero learning curve) or pursue a higher performance machine and invest in the future? This decision would impact their tooling and in-house molding business for many years to come.

Wepco decided to break stride with their current equipment and purchased a Hurco VMX 30 machining center from Brooks Associates (Norwell, MA). Wally and David weighed several factors in their decision-making process:

- Flexible, open-architecture Hurco control

- Mechanical design features such as RPM & maximum feed rates

- Local Support & Service

- Favorable references from local shops

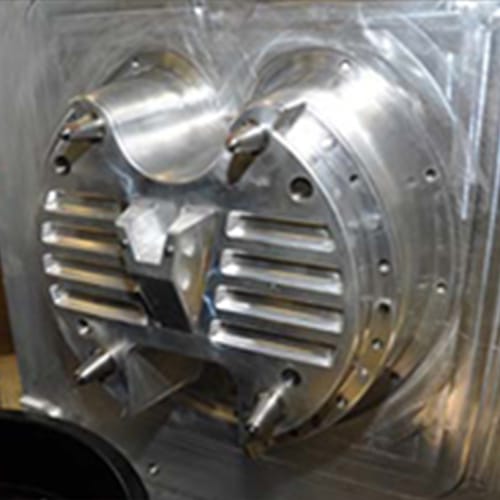

Although difficult, their decision proved to be advantageous. The Hurco VMX30 delivered superior performance and part quality in a fraction of normal cycle times. Wepco primarily focuses on aluminum molds for prototype and short-run batches. The Hurco 12,000 RPM spindle (coupled with Hurcos advanced motion control system) was able to drastically reduce total part cycle time by as much as 200-300% in some cases (with no loss of accuracy or finish). Before Ultimotion™ Wepco would finish machine at 40 IPM. Now they are able finish machine at rates from 125-350 IPM! These productivity gains translated to hidden profits in existing jobs and added capacity for future work.

The VMX30 also offered opportunities for new, more-efficient processes such as hard machining. Wepco routinely machines 58 Rc mold inserts made from S7 tool steel. Parts come off the machine ready for assembly in the mold. Success with this type of material is due to advanced cutter technology and the Hurco Ultimotion™ software which optimizes machining RPM and federates based on part geometry. Ultimotion™ routinely reduces cycle times on 3D programs by as much as 40%.

Wepco was so encouraged by the VMX30 productivity that they added a second Hurco VMC shortly thereafter (Hurco VMX24). Both machines have proven to be reliable sources of production for Wepco’s tool room.

WEPCO PLASTICS was established in 1985 and has grown steadily to over forty employees. Wepco now owns a modern 10,000 square foot facility. Wepco attributes this growth and planned future growth to our attention to detail and quality, as well as customer satisfaction by diligently following specifications, meeting delivery dates and offering competitive prices on short run injection molding.

Small Manufacturing Company Discovers Big Productivity With New Hurco VM1

Essex, CT—Unlike many manufacturing companies today Kenyon Labs enjoys relatively little outside competition. Tucked away in this quiet New England town is a global company with a product that spans many different industries. Until recently, Kenyon’s biggest competitors were the internal issues of setup, fixturing and programming time.

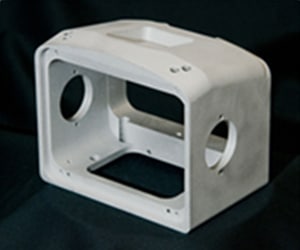

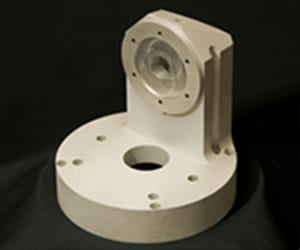

Founded in 1960, Kenyon Labs manufactures gyroscopes that were originally used for aerospace and nautical navigation purposes. Since then Kenyon’s market has expanded into other applications such as cinematography and televised sporting events. Every “Steady-Cam” unit in use today, be it in a Hollywood blockbuster film or for NFL game coverage contains Kenyon’s durable and highly accurate gyroscopes.

With existing manual equipment, Ron Denman (owner) found it increasingly difficult to keep up with new orders while supporting units in the field. (Kenyon has thousands of customers all over the world with many of the gyros lasting decades!) The gyro housings and gimbals are small but complex, often requiring six-sided machining with certain features that must be concentric within .0001″ (concentricity is critical for long-term bearing life). To machine all these features within the required tolerances manually was complex and time consuming.

Kenyon purchased their VM1 (their first CNC machine) in December 2002 and since then have experienced dramatic gains in productivity. On their first job Kenyon cut the required setups from ten to three. Cycle time was cut from 90 minutes to 11 minutes. Consequently, leadtimes on new units and repair jobs have been cut markedly. As a first-time CNC user, Denman was concerned about absorbing a learning curve while still maintaining day-to-day operations.

The Ultimax control is conversational, and is designed for an operator who may not have Gcode experience. “I’m really surprised by how simple and powerful the control is”, says Denman. “A first-time user can literally be making good parts after a few days of training.”

Kenyon is continuously finding new jobs to put on their machine and new ways to process parts. Because of the higher spindle speeds and removal rates, they have the potential to eliminate some expensive casting processes. This not only brings their costs down, but cuts lead times for raw materials. “We’ve got the best of both worlds now,” remarks Denman. “We’ve gained speed and ease-of -use without sacrificing accuracy or quality.”