In the world of abrasive waterjets there are basically 2 options when it comes to pumps – the hydraulic intensifier and the direct drive crankshaft style. For many customers figuring out which is a better choice for their needs can be confusing and end up getting overlooked during the buying process. This could prove to be a huge mistake, the pump is the heart of the machine. If the heart stops beating, it’s game over. Finding a pump that’s reliable, easy-to-service, efficient to run, and durable for the long haul is a critically important component of selecting an abrasive waterjet system.

Generally speaking OMAX is the primary manufacturer for direct drive style pumps, while the majority of their competition have elected to go with a hydraulic intensifier. You may be thinking is that because everyone has figured out that the intensifier is a better choice? OR Does OMAX have a better mousetrap and they refuse to change to the intensifier simply to reduce manufacturing costs? To sort it all out let’s consider the origins of these pumps and how they work.

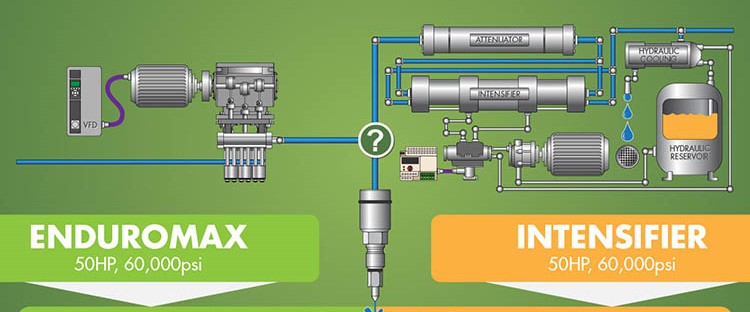

The hydraulic intensifier was invented prior to the direct drive pump. It utilizes a complex system that requires an electric motor, hydraulic pump, oil reservoir, manifold and plunger. The direct drive was invented to simplify the mechanics of this down to just the electric motor, which is powering a crankshaft-driven set of plungers. Due to the incredible inefficiencies found in the hydraulic losses of the intensifier pump, the direct drive pump can deliver a higher percentage of its electrical power to the cutting nozzle.

At the end of the day what matters for waterjet operation is the horsepower at the nozzle, not the horsepower at the pump. That’s where the direct drive and the hydraulic pump have substantial differences. It takes a 70hp intensifier pump to deliver the same horsepower to the nozzle as a 50 horsepower direct drive pump. The intensifier is only 60% efficient while the direct drive is 85% efficient. That adds up to a lot of wasted electricity with an intensifier pump to get the same cutting speeds as the more efficient direct drive.

Another cost savings with a direct drive pump is in water usage. As water becomes more of a precious resource, and waste water more of a regulated resource, it makes a lot of sense to seriously consider the amount you’re going to need for your waterjet pump. A direct drive pump typically uses 60-80% less water than an intensifier pump because it does not require a separate water supply for the cooling of the hydraulics.

Brooks Associates encourages our customers to do their homework. The direct drive style pump provides a more steady pressure for smoother edge finish, uses less power and less water, and is far quieter during operation than the intensifier pump. We recommend getting a demo of both styles of pumps before making a purchase.