INDIANAPOLIS—Charles Boyce, owner of Boyce Technologies in New York, broke the Hurco USA record for the largest single purchase of Hurco CNC machines in the division’s history. Boyce Technologies designs and manufactures security and communications equipment for the mass transit market, including emergency response systems, intercom systems, security alarm systems, radio and wireless networks, and customer information display systems. Their newest system, called Help Point, is what subway riders in New York City use to get information and to get help when needed.

INDIANAPOLIS—Charles Boyce, owner of Boyce Technologies in New York, broke the Hurco USA record for the largest single purchase of Hurco CNC machines in the division’s history. Boyce Technologies designs and manufactures security and communications equipment for the mass transit market, including emergency response systems, intercom systems, security alarm systems, radio and wireless networks, and customer information display systems. Their newest system, called Help Point, is what subway riders in New York City use to get information and to get help when needed.

Founded in 2007, the company has grown from one employee, the owner Charles Boyce, to 60. Boyce Technologies received the 2015 Inc. Top 5000 Honors with a rank of #166 due to its 3-year growth rate of 2,442%. Inc. also ranked Boyce #16 of the Top New York Companies, and #3 for Top Manufacturing Companies.

Charles Boyce purchased his first Hurco CNC machine from Hurco distributor Brooks Associates in 2008 before he had a commercial building. “The first VMX30 was installed in the living room. We had to cut the ceiling joists away to allow the Z travel to retract fully,” said Boyce.

With this latest order, the Hurco fleet of CNC machines at Boyce Technologies numbers 21. Boyce credits the ability to choose the best manufacturing technology as one of the key components that has made his company successful in developing technology solutions for its customers in the mass transit sector. Specifically, the Hurco control powered by WinMax® provides the versatility required to go from concept to finished part. The control also has the specifications to handle large program part files with a solid state drive that has 2GB of RAM, a 2 GHz processor, 64GB hard drive, and Hurco’s patented motion system, UltiMotion, that provides up to 10,000 blocks of lookahead.

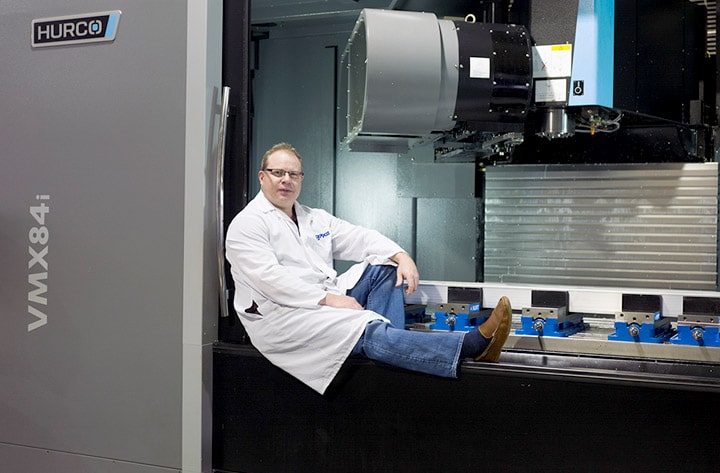

In addition to the original 3-axis VMX30, seven Hurco VMX42i mills, five VMX84i mills, two high-speed mills, and a lathe with live tooling, Boyce has invested in high-end 5-axis technology from Hurco with his purchase of two VMX42SRTi swivel head 5-axis mills and three trunnion style 5-axis mills. The VMX42SRTi is equipped with a C-axis, torque, rotary table that has unlimited angular movement. The extra large table delivers exceptional manufacturing flexibility to manufacture a high mix of parts because the additional table space can be used for secondary operations or 3-axis work.

Hurco recently released the MAX5 control console, which features numerous ergonomic design features focused on operator usability. “Our trust in Hurco has led us to purchase the largest quantity of Max 5 controllers in the world, making our new LIC (Long Island City) production center one of the most advanced production centers in America,” said Boyce.

In addition to selecting the right CNC technology to develop technology solutions, Boyce credits his team of designers, CAD drafters, CNC programmers, machinists, welders, engineers, assemblers, field technicians, project managers, software designers, salespeople and administrative support for the company’s rapid success. “Together, they find innovative solutions to deliver emergency response systems, intercom systems, security alarm systems, radio and wireless networks, customer information display systems and integrated software that are reliable in the harsh conditions of mass transit and other such venues. They are a team that solves problems and takes pride in the work they do,” said Boyce.