about.

OMAX Series

See all the abrasive waterjet systems available in the OMAX line and explore the footprint, cutting area and positional accuracy of each.

OMAX 2626

The OMAX 2626 abrasive waterjet system is designed to be a highly precise, compact machine to give customers everything a waterjet has to offer while taking up minimal floor space, only 72” x 116”. It might be the smallest of our cantilever systems but it can definitely still get the job done. The rigid tank design and precision ground X and Y axis allow it to stand up to even the toughest job in a high production environment. Many shops have dedicated small part jobs running around the clock on their 2626 systems.

OMAX 2652

The OMAX 2652 abrasive waterjet system is the flag ship original system built by OMAX. This system was built to last with many of the first machines, now nearly 25 years old, still in daily operation several of which are located in New England. The 2652 is the perfect machine for cutting 2′ x 4′ sheets with high precision and minimum taper for protoyping, medical components, R&D work, or educational institutions. According to one Massachusetts machine shop owner his 2652 can “cut parts that don’t require extremely tight tolerances much faster than wire EDM.”

OMAX 5555

The OMAX 5555 abrasive waterjet system is the perfect machine for shops needing a larger table size with the use of minimal floorspace. The 5555 is able to hold a full 5’ x 5’ sheet which gives customers the ability to feed a 5’ x 10’ sheet through it for the occasional large part job. This machine features a fully enclosed precision ballscrew drive system that is sealed for complete protection from the elements. The newest of the cantilever style machines this unit has all the benefits of the 20 years of engineering experience the OMAX team has to offer.

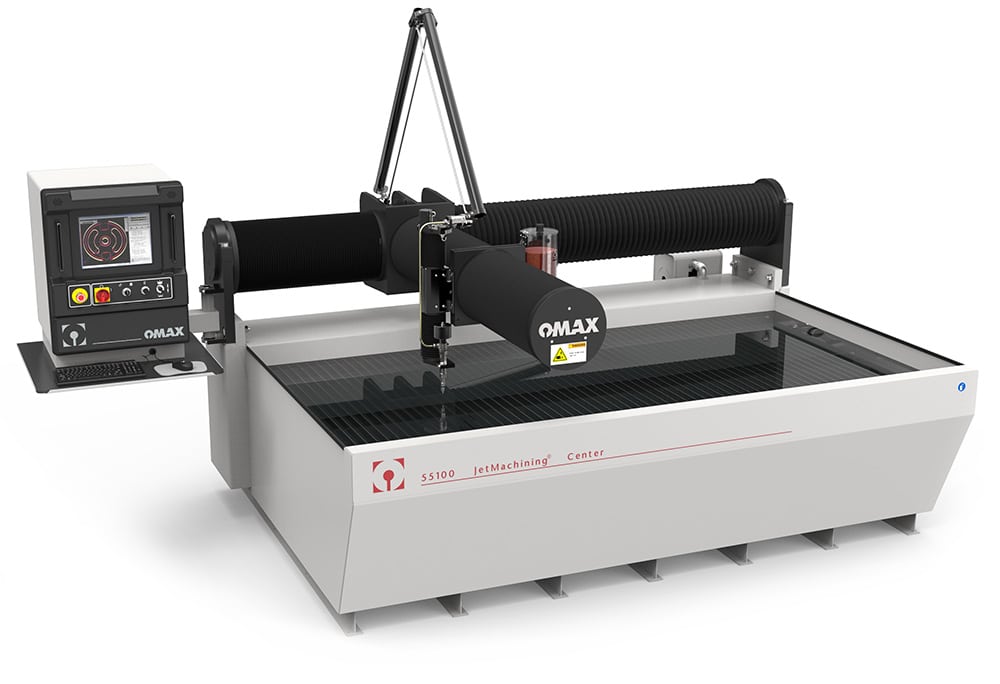

OMAX 55100

The OMAX 55100 abrasive waterjet system is the largest of the cantilever designed systems with the ability to load a full 5’ x 10’ sheet and cut 55” x 100”. The 55100 has been the best selling machine for OMAX for years because of its ideal system size and incredible reliability. For customers looking for a true work horse this machine is for you. Many local shops have started with the 55100 and their waterjet operation has grown to 3 or 4 machines!

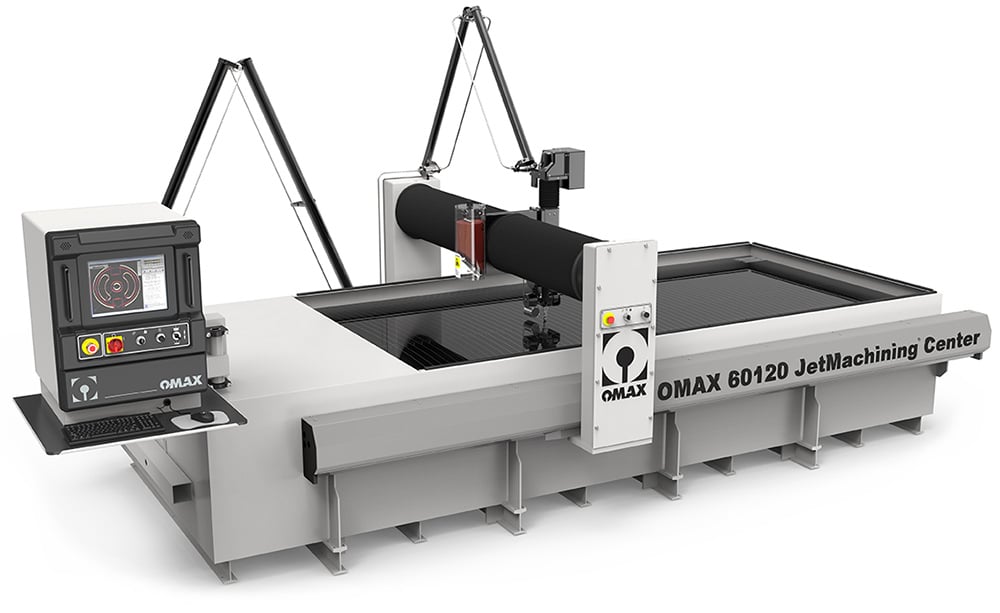

OMAX 60120

The OMAX 60120 abrasive waterjet system is the ideal large table, bridge style machine. Utilizing the revolutionary, patent-pending Intelli-TRAX linear drive system this machine is able to give premier precision on a large scale machine. Intelli-TRAX is a virtually maintenance free drive system guaranteed to maintain accuracy. The Intelli-TRAX system was designed specifically for the harsh environment of abrasive waterjet cutting ensuring it has the rigor to withstand the test of time. Even on this larger table the OMAX machine is still able to offer fully submerged cutting to maintain that clean, quiet cutting environment customers have to come to expect.

OMAX 80160

The OMAX 80160 JetMachining® Center one of our larger bridge-style waterjet machines, and it is the only bridge style model using a completely sealed and protected Ball Screw Drive System. The OMAX 80160 JetMachining Center is robust and reliable for shops using larger stock and needing the convenience of unobstructed material loading provided by the bridge-style Y-axis. This model comes standard with a Bulk Abrasive Delivery System and the OMAX MAXJET® 5i Nozzle. It rapidly and precisely gets the job done, maximizing both machining time and profit margins.

OMAX 80X Series

The OMAX 80X abrasive waterjet system provides a full 6’ x 12’ cutting area with space for clamping and fixturing inside the table as well. The unique design of the OMAX bridge systems allows the entire bridge to be parked over the air dome (utilized to raise and lower the water level for submerged cutting feature) thus providing completely unobstructed access to the cutting area. Customers find this ideal for easy loading and unloading of material and parts. Not only does it increase their efficiency it also protects their investment. No one wants the risk of hitting an expensive cutting head, possibly a 5 axis head, while simply trying to load material for the next job. This unique design also provides ergonomic, safe operator access to the entire table.

OMAX 120X Series

The OMAX 120X abrasive waterjet system is one of the largest machines available with a cutting area of over 10’ x 20’, with extensions available. Not only does the 120X utilize the high accuracy, incredible durable OMAX Intelli-TRAX linear drive system but it also offers the ability to run multiple jobs at one time. One key advantage of this drive system is the ability to run multiple bridges simultaneously. Several New England customers are able to run different jobs on the same machine by utilizing dual bridge operation. This provides the maximum efficiency with the lowest cost of investment available. Like all OMAX bridge tables it has full access for loading and unloading material as well as fully submerge cutting for a clean and quiet operation.