about.

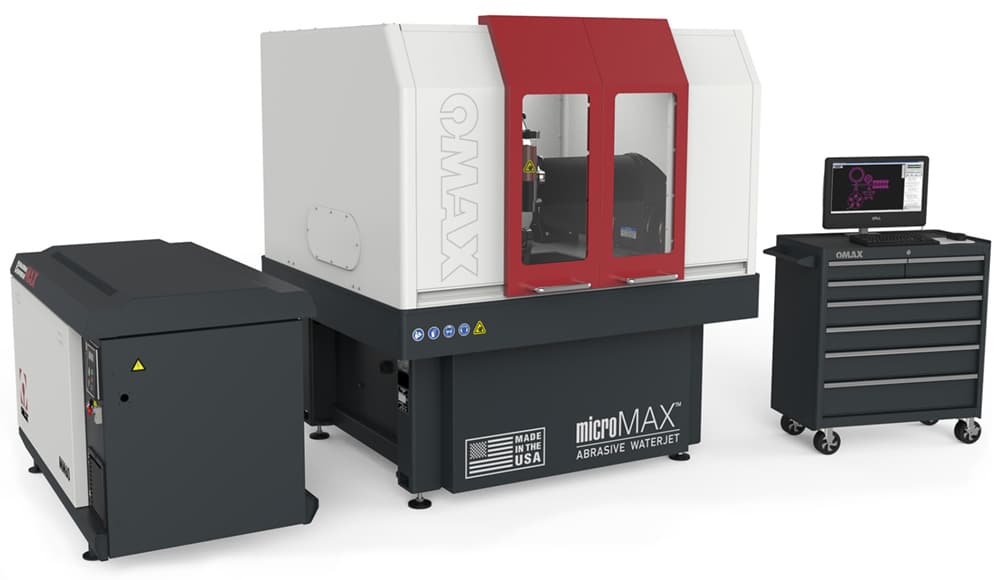

OMAX MicroMAX Series

The MicroMAX JetMachining Center is the ideal solution for ultra-precision abrasive waterjet machining. Utilizing advanced high-precision optical linear encoders, innovative vibration isolation, and proven software control systems, the MicroMAX JetMachining Center is capable of a positioning accuracy of less than five microns while retaining all the advantages of abrasive waterjet machining. The MicroMAX can machine stainless steel, titanium, carbon fiber, PEEK, glass, nitinol, graphite, copper, composites, laminates, and more, with high precision and smooth finishing, for either prototyping or production.

MicroMAX

For MicroMachining there’s no better abrasive waterjet solution than the newest release of the OMAX MicroMAX JetMachining Center. It’s the perfect solution for extreme precision abrasive waterjet machining on a micro machining level. In order to achieve positioning accuracy unlike anything else on the market, less than five microns, the MicroMax JetMachining Center uses unique vibration isolation materials, high-precision optical linear encoders, and the proven advanced OMAX software control system. This allows for all of the advantages of high precision without losing the inherent advantages of running a waterjet such as no HAZ, nearly unlimited material types, and no tool changes. The MicroMAX can machine brass, stainless steel, granite, titanium, nickel, carbon fiber, glass, aluminum, copper, tool steel, composites, laminates, and more, while maintaining a smooth finish and incredible accuracy. The MicroMAX is the ideal micro machining tool regardless of whether you’re using it for prototyping or large scale production.