Jtekt › Horizontal Machining Centers

With superior performance that is distinctly JTEKT Machinery, we manufacture state-of-the-art horizontal machining centers for efficient production and high-precision machining. JTEKT Machinery horizontal machining centers provide industry-leading speed, rigidity, and accuracy to keep machine shops productive.

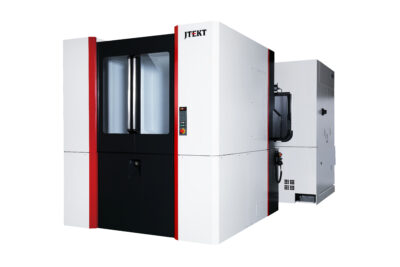

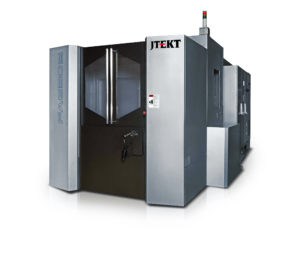

Designed to achieve remarkable speed and production reliability, JTEKT’s FH5000 Series meets the growing demand for high metal removal rates, short cycle times and superior surface finishes. It features standard 60-tool ATC capacity, along with a 15,000 RPM, 50 HP (37 kW), 303 Nm (223 ft-lbs.) high acceleration spindle. Equipped with a direct drive B-axis table featuring an index time (90°) of 0.7 seconds – the FH5000’s spindle design, preload system and high torque features allow manufacturers to take advantage of more aggressive, high-volume machining in a compact footprint.

Pallet Range

21.65″ x 21.65″ (550 mm x 550 mm)

2,200 lb (1,000 kg) Capacity

Ø2.95″ x 20.07″ (Ø75mm × 510mm) to

Ø4.72″ x 21.45″ (Ø120mm × 545mm)

Models

FH5000S-i

FH5500S-i

FH5500SX-i

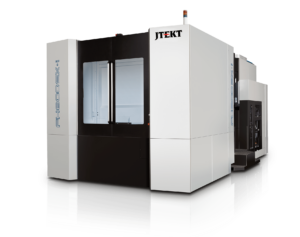

The FH12500SX-i is a powerful, high-speed horizontal machining center featuring an upgraded heavy duty 6,000 RPM gear driven spindle with 1,620 ft.lbs of torque. The FH12500 series platform has available spindle options for 8,000 RPM or 15,000 RPM. The 12500SX-i utilizes a cylindrical roller guide design for increased speed as well as dual ballscrew drive on the Y and Z axes for increased rigidity. The FH12500 series is the perfect option to reduce cycle times of large components with the rapid feedrate of 1,654 ipm and a 3.7 second chip to chip tool change time.

Pallet Range

49.2″ x 49.2″ (1,250 mm x 1,250 mm)

11,000 lb (5,000 kg)

Models

FH12500SX-i

FH12500SW-i

Designed to achieve remarkable speed and production reliability, JTEKT’s FH5000 Series meets the growing demand for high metal removal rates, short cycle times and superior surface finishes. It features standard 60-tool ATC capacity, along with a 15,000 RPM, 50 HP (37 kW), 303 Nm (223 ft-lbs.) high acceleration spindle. Equipped with a direct drive B-axis table featuring an index time (90°) of 0.7 seconds – the FH5000’s spindle design, preload system and high torque features allow manufacturers to take advantage of more aggressive, high-volume machining in a compact footprint.

Pallet Range

21.65″ x 21.65″ (550 mm x 550 mm)

2,200 lb (1,000 kg) Capacity

Ø2.95″ x 20.07″ (Ø75mm × 510mm) to

Ø4.72″ x 21.45″ (Ø120mm × 545mm)

Models

FH5400J – Highspeed Linear Way

FH450S – Heavy Duty Linear Way

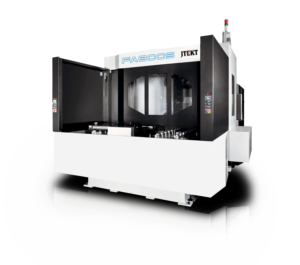

A step up from a 400 mm size machine, the Wele HMC500 offers larger work envelope and superior production value for high-speed operations. The HMC500 features a 30 HP, 15,000 RPM built-in motor style, with 3.3 seconds ramp up 0 to 15,000 high-speed spindle makes the most of your production.

The FH550SX is a powerful, high-speed horizontal machining center featuring an 8,000 RPM high-torque spindle, with an option of 15,000 RPM spindle, and a rapid feedrate of 2,362 ipm (60 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity.

The column moving type machine series is a new generation of horizontal machining centers. The CMH500XL comes with a CT 40, 20 HP, 8,000 RPM spindle and a 40 automatic tool changer as a standard feature. This machine is designed to be able to machine long difficult-to-handle applications.

Pallet Range

19.68″ sq. (500mm) to 21.65″ sq. (550mm)

1,760 lb (800 kg)

Ø31.50″ x 39.37″ (Ø800 mm x 1,000 mm) to

Ø33.46″ x 39.37″ (Ø850 mm x 1,000 mm)

Models

FH500J – Highspeed Linear Way

HMC500 – Compact Highspeed Linear Way

FH550SX – Heavy Duty Linear Way

CMH 500XL – Column Moving Machining Center

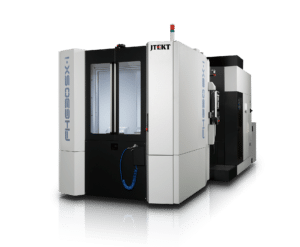

The FH630SX-i is a powerful, high-speed horizontal machining center featuring an 8,000 RPM spindle, with the option of a 15,000 RPM high-torque spindle, and a rapid feedrate of 2,362 ipm (60 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity.

The FA630S is a heavy-duty horizontal machining center featuring a robust column and bed, box guideways, and a powerful spindle. These features allow for powerful machining with high accuracy.

Developed best-in-class 5-axis machine for a 630 mm platform, the FH630SX-i 5-Axis is designed for complex part machining. It features an 8,000 RPM high-torque spindle, with the option of a 15,000 RPM high-power, multi-use spindle, and a replaceable taper design for high maintainability. The tilting spindle comes with a robust C-axis drive train and an enlarged C-axis swivel range of 230 degrees for wider components.

Pallet Range

24.8″ sq. (630mm)

3,310 lb (1,500 kg)

Ø46.06″ x 49.21″ (Ø1,170 mm x 1,250 mm)

Models

FH630SX-i – Heavy Duty Linear Way

FA630S – Heavy Duty Box Way

FH630SX-i 5-Axis – 24.8″ Pallet High Power/Speed Five Axis

The FH800SX-i is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 2,127 ipm (54 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity. The expansive work envelope allows for large-part machining.

The FA800S is a heavy-duty horizontal machining center featuring a 6,000 RPM direct-drive spindle, with options of a 6,000 RPM geared-head spindle or 15,000 RPM spindle, and a rapid feedrate of 944 ipm (24 m/min). The machine’s robust column and bed, box guideways, and large workpiece swing allow for powerful machining with high accuracy.

Pallet Range

31.5″ sq (800mm)

5,500 lb (2,500 kg)

Ø39.4″ x 25.6″ (Ø1,000 mm x 650 mm) to

Ø63″ x 51.2″ (Ø1,600 mm x 1,300 mm)

Models

FH800SX-i – Heavy Duty Linear Way

FA800S – Heavy Duty Box Way

The FH1000SX is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 2,126 ipm (54 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base to suppress vibration in the heaviest of cuts.

The FA1050S is a heavy-duty horizontal machining center featuring a 6,000 RPM direct-drive spindle, with options of a 6,000 RPM geared-head spindle or 15,000 RPM spindle, and a rapid feedrate of 944 ipm (24 m/min). The machine’s box guideways, robust column and bed, and large workpiece swing allow for powerful machining with high accuracy.

Complex 5-axis machining is achieved with the FA1050S 5-Axis trunnion table. Its dual-drive mechanisms support heavy workpieces, while the high-resolution rotary encoders ensure precise positioning during simultaneous 5-axis applications.

Pallet Range

39.4″ sq. (1000mm) to 41.3″ (1050mm)

6,600 lb (3,000 kg)

Ø70.9″ x 63″ (Ø1,800 mm x 1,600 mm) to

Ø72.8″ x 61″ (Ø1,850 mm x 1,550 mm)

Models

FH1000SX – Heavy Duty Linear Way

FA1050S – Heavy Duty Box Way

FA1050S-5Axis – 41.3″ Pallet 5-Axis Trunnion Box Way

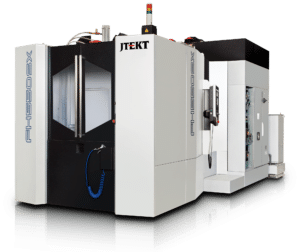

The FH1250SX is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 1,654 ipm (42 m/min). This machine has cylindrical roller guides for increased speed, and dual ballscrew drive on the Y and Z axes and a Meehanite cast iron base for maximum rigidity.

The FH1250SW is a quill-spindle horizontal machining center designed for heavy-duty operations. This machine’s unique 3,000 RPM spindle is ideal for boring and deep drilling, allowing workpieces previously requiring two operations to be completed on a single machine.

The FH1250SX 5-axis is a five-axis horizontal machining center designed for complex, large part machining. It features a 15,000 RPM integral tilting spindle and rapid feed rates of 1,260 ipm (32 m/min) on the X and Y axes and 1,654 ipm (42 m/min) on the Z axis.

Pallet Range

49.2″ sq. (1,250mm)

11,000 lb (5,000 kg)

Ø94.5″ x 70.9″ (Ø2,400 mm x 1,800 mm)

Models

FH1250SX – Heavy Duty Linear Way

FH1250SW – Heavy Duty Boring Bar Quill

FH1250SX-5Axis – 49.2″ Pallet Versatile 5-Axis Swivel Spindle

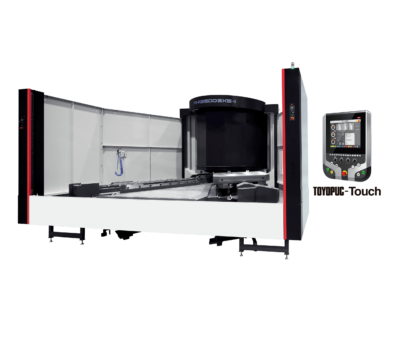

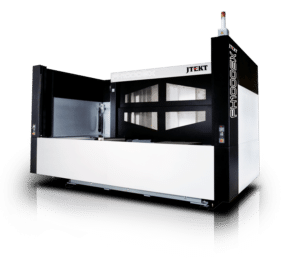

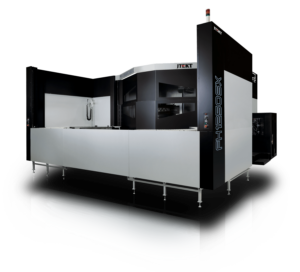

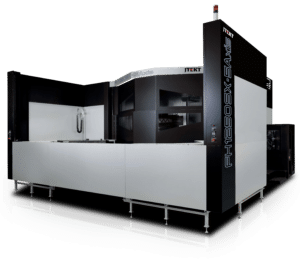

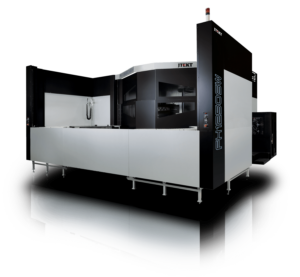

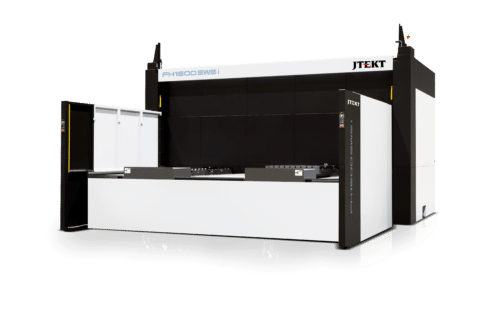

Toyoda’s FH1600SW-i horizontal machining center features the largest work envelope in its class with a maximum swing of ⌀126″ (⌀3,200 mm) and a workpiece height of 83″ (2,100 mm). Engineered for heavy cutting, the FH1600SW-i’s 5.9″ (150 mm) diameter quill spindle allows for powerful cutting with high material removal rates.

Pallet Range

63″ x 49.2″ (1,600 mm x 1,250 mm)

17,600 lb (8,000 kg) (Opt. 32,000 lb)

Ø126″ x 83″ (Ø3,200 mm x 2,100 mm)

Models

FH1600SW-i – Heavy Duty Boring Bar Quill