Hurco › Vertical Machining Centers

Some machine tool companies want you to think there’s really little difference between machine tool brands. Hurco can’t disagree more. The important thing is to understand the real differences and select the equipment that is best for your operation.

Hurco’s differences are very pronounced, though not all are obvious at first glance. The Hurco control allows shops to choose the most efficient way to program parts for each job. It is flexible and powerful primarily because of its simplicity. That’s also why Hurco offers such an intelligent breadth of machining centers.

Each series has its own well-defined place in the market. Chances are, you’ll find just what you need in one of Hurco’s 12 machining center models.

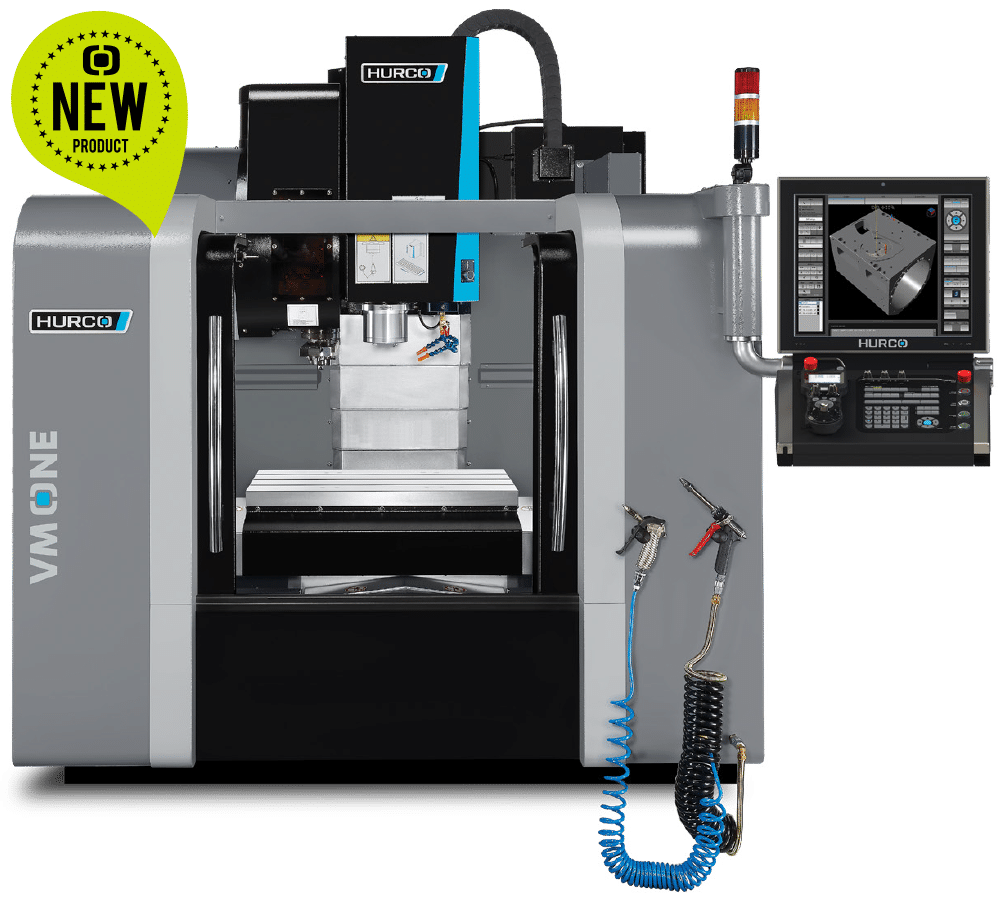

Hurco was built on dreams, hard work, and calculated risks. We’ve grown, but haven’t forgotten our roots. The most popular Hurco of all time was the VM1 that was released 20 years ago. More important than the number of units sold, was the role the VM1 played in helping machinists make their dreams come true.

Repeatedly, one machinist with grit, determination, and a dream embraced the power of Hurco technology and started their shop with a new VM1. As these shops grew, Hurco grew. Their success is part of our culture. We’re excited to introduce the revitalized version of the popular VM1.

The VM Series offers powerful machining with a compact footprint, and absolutely the best value on the market.

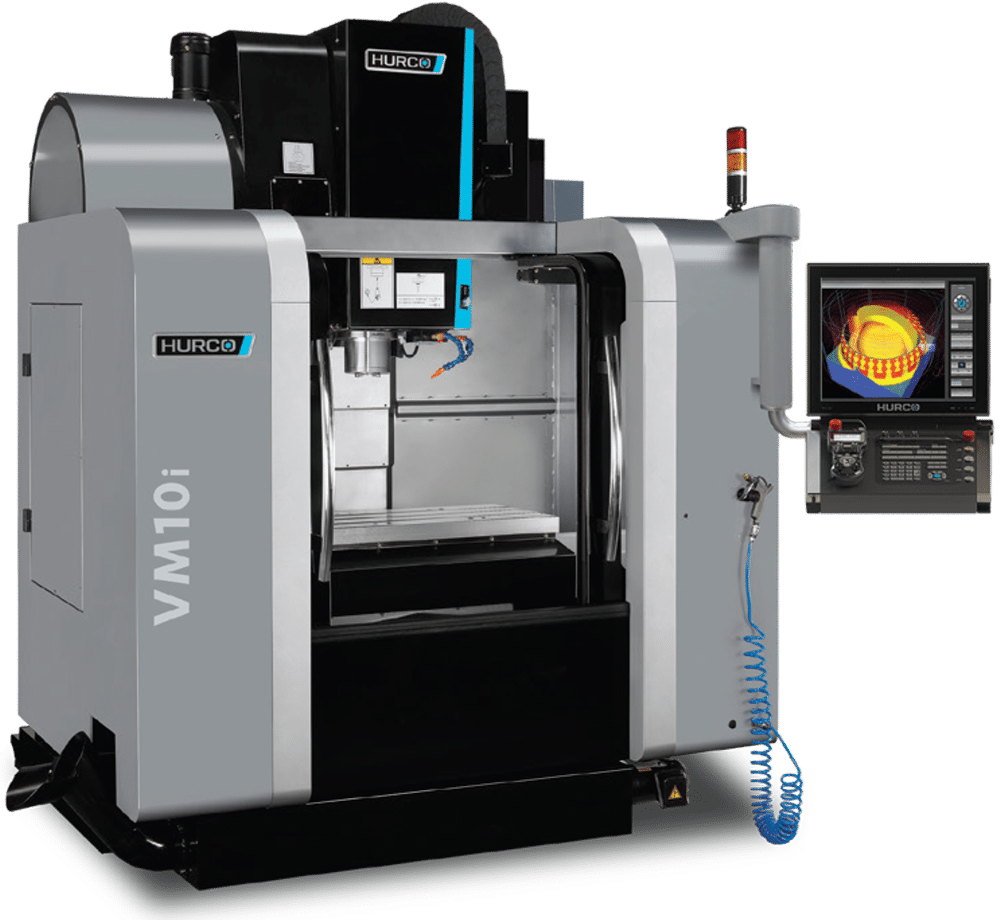

VM5i

VM10i (26x16x20)

VM20i (40x20x20)

VM30i (50x20x20)

VM10HSIi (26x16x20)

The VMX Series is our signature line of machining centers and takes machining to the next level. These machines deliver high performance capabilities to any machining application. The VMX was created specifically to take advantage of the integrated Hurco control and its powerful WinMax® software. Options include high speed spindles, large tool-change capabilities, and significant production-enhancing software.

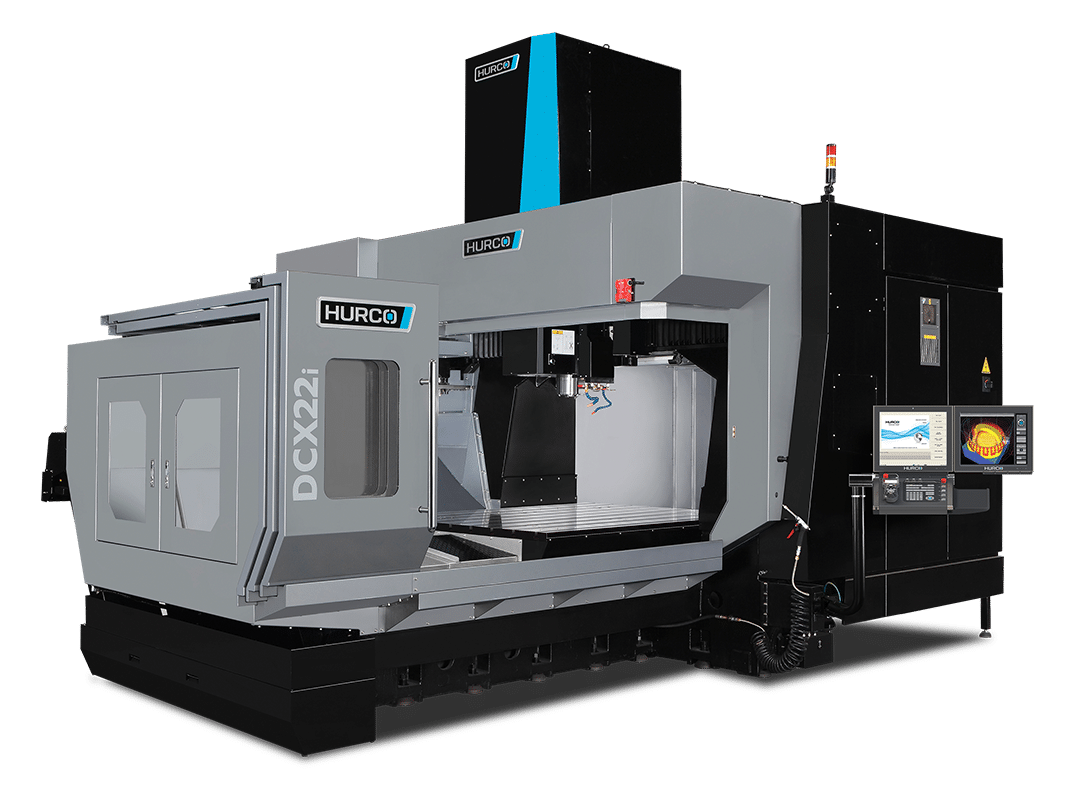

According to our customers, the aerospace and energy sectors are requiring bigger and bigger parts. Incorporating our advanced control technology with our design and manufacturing expertise, we recently introduced this large machining center (DCX22) to support these customers.

DCX22i (86.6×66.9×29.5)

DCX32i (126×82.7×36.2)

DCX42i

DCX32-5si