about.

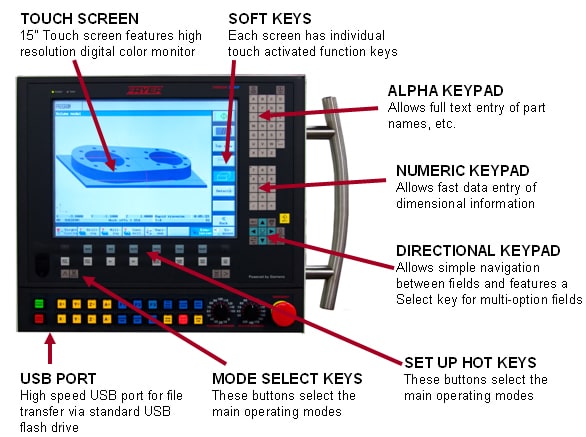

Fryer 2100 CNC Control

The Fryer Touch 2100 control is based on the powerful and flexible Siemens 840D platform. The 2100 provides world class technology and advanced features in an easy-to-use control does without compromising on functionality. Designed for maximum productivity, the 2100 gives you everything you need to make parts fast and efficiently: A full range of pre-programmed machining cycles, tool life management, set-up hot keys, conversational or NC (G Code) programming, ultra high speed machining, advanced solid model graphics and an automatic geometry creator just to name a few. The Siemens Touch 2100 out-performs any control in its class on the market today.

Digital Drives

- Compact Digital Control System (DCS)

- Spindle drive, axis drive and control CPU integrated digitally

- Extremely accurate linear and circular interpolation

- Ultra reliable design featuring 15 years meantime between failures

Digital Motors

- Ultra precise AC brushless motors

- Asynchronous spindle motor accelerates to 10,000 RPM in 1 second

- Absolute encoders remember machine position even during a power failure

- ACC/DEC faster than standard analog systems

Tool Management

- Tool table graphically shows tool type and geometry

- Workpiece count and tool-life monitoring with sister tools

- Tool radius compensations with approach and retract strategies

- Connection to RFID tool identification system – MOBY E

Connectivity

- High speed networking uses standard Ethernet interface

- Available with wireless router

- Remote monitoring allows you to view control options from anywhere

Automation

- Connects to all popular robots

- Connect automatic pallet shuttles

- Automatic probing with gauging

- Lights out machining capability

5-Axis

- Inverse time function

- Spline interpolation for 5-axis

- Tool orientation programming using vector or RPY angles – TRAORI function

- 3D tool nose radius compensation

Multi-Tasking

- Mill/turn using live tooling and ‘C” axis

- Grinding spindles with ID and OD integrated into turning center

- Milling applications feature gauging, calculations and re-machining

- Integrated welding, turning and grinding

Offline Programming

- Fully integrates with all CAD/Cam systems

- Edit programs at the desktop or at the control quickly with search, replace and auto-start features

- Fully simulates control – ideal for training new operators without losing valuable machine time