about.

Fryer Horizontal Machining Centers

Fryer builds heavy duty performance into every machine we ship. Solid Box way construction with the highest quality components and a list of industry leading features result in a versatile and robust machine. Our digital control system features ease of use and high performance to maximize machining output.

Horizontal Machining Centers

The Fryer HR Series are high performance box way horizontal machining centers designed for your most demanding applications. The high torque 40 HP spindle motor and standard 6,000 RPM 50 taper spindle provide the rigidity and torque needed. Extra-large castings, ballscrews and bearings provide accuracy and vibration dampening. The user friendly 2200 CNC allows simple shop floor programming or G code programs to be run with ease.

Horizontal Boring Mills

The Fryer HB Series boring mills are heavy duty machines designed for high precision machining. These machines are equipped with a 40 tool ATC, built in indexing table (HB-70 only), bar type spindle with 20” travel and a powerful 40 HP spindle motor. Rugged box way construction and high precision ballscrews ensure high performance cutting and high accuracy tolerances. The user friendly 2200 CNC allows shop floor programming for single piece runs or G code programming for high production.

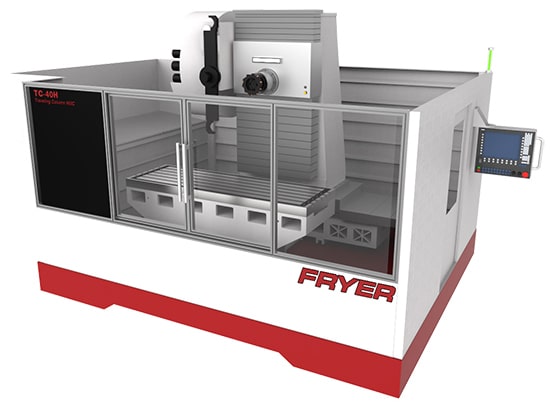

Horizontal Traveling Column

The new Fryer TC-H Series features a fixed table and traveling column design. The fixed table allows table loads of more then 10,000 lbs. while offering versatility in part fixturing. The horizontal traveling column features high rigidity linear ways and a Swiss made high precision rack and pinion drive for the X axis

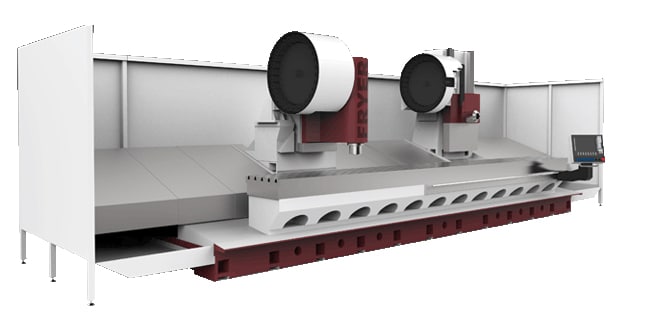

Duplex Traveling Column

The Fryer TC-D Series features two traveling columns for the ultimate in versatility. Custom configured for your application, the machine can have horizontal, vertical or mixed spindles. The powerful Siemens control system allows separate programs to be run for each spindle. Please contact the factory for information and pricing.