training & service.

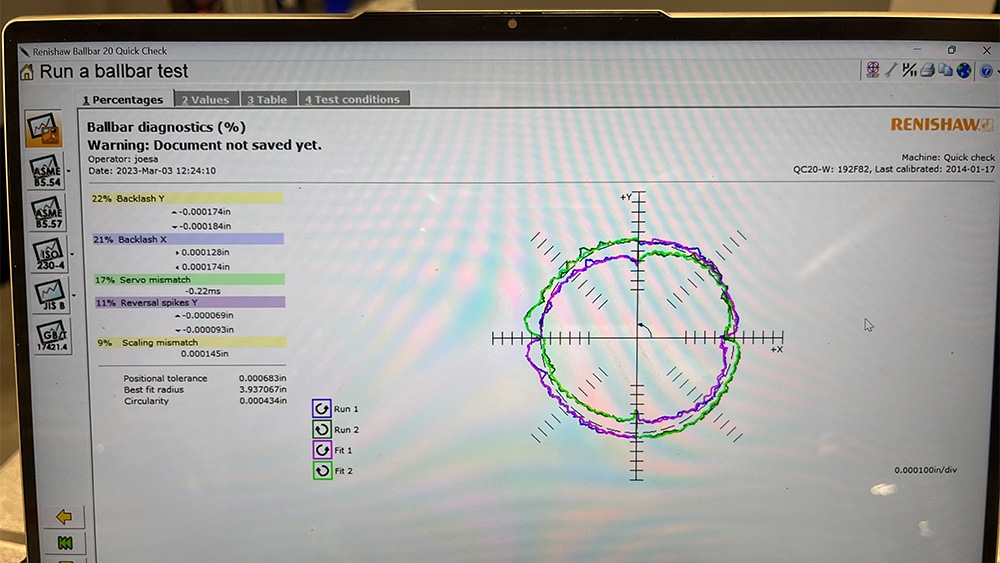

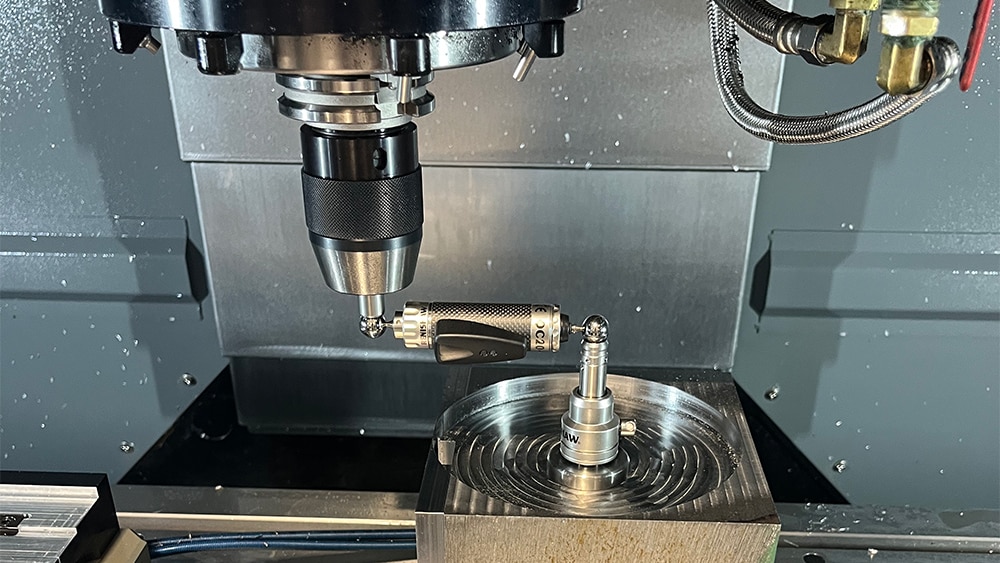

At Brooks, training and service is our top priority. Brooks stands behind its customers and equipment with highly skilled, factory trained/certified service engineers. We offer annual service contracts for OMAX and Hurco Machines. Contact us now with your installation, training, preventative maintenance, and service needs. We are here to help with all of your precision machine tools needs.